Machine-learning design of ductile FeNiCoAlTa alloys with high strength

作者:Ma, En

Main

Metallic alloys with extraordinary strengths are highly sought after for challenging structural applications. The state-of-the-art bulk alloys have now reached yield strength (σy) of approximately 2 GPa while retaining adequate tensile ductility (ε exceeding 8%)1,2,3,4. For example, such a strength–ductility combination has been accomplished in a few ultra-strong steels1,2,3, including deformed and partitioned (D&P) medium-Mn steels2 with C concentrations of approximately 0.18–0.47 wt%. However, these steels have inadequate work hardening capability and, consequently, often suffer from extensive Lüders bands or Portevin–Le Châtelier bands. As such, much of the reported uniform elongation (εu) in standard uniaxial tensile test consists of serrated plastic flow caused by C solute-induced deformation bands, rather than truly uniform elongation. When Lüders bands are absent, such as in some 2-GPa maraging steels, εu is limited to approximately 3.8% (ref. 1).

One potential pathway to surpass these steels in reaching high σy and large εu simultaneously is to resort to recently emerging high- and medium-entropy alloys (HMEAs), in which multiple principal elements are adopted to form compositionally complex alloys. However, this approach has not yet fulfilled its promise. Although many high-entropy alloys (HEAs) have been developed, often on the basis of a face-centred cubic (FCC) phase (dominant) with high ductility and toughness, their yield strength is generally relatively low5,6. In addition to solute atoms (or local chemical order (LCO))4, grain boundaries7 and twin boundaries8, nanoprecipitates can mitigate, to some extent, the strength–ductility trade-off in numerous alloys, such as Al alloys9, steels1,10,11 and Ni-based superalloys12,13, in which the nanoprecipitates act as dislocation obstacles and sources14,15,16 and encourage dislocation entanglement to increase strain hardening. Unfortunately, as summarized later, these nanoprecipitation-hardened HEAs manifest a σy below 1.2 GPa (refs. 17,18). This is a result of the limited fraction (less than 55 vol%) of nano-scaled multicomponent intermetallic precipitates (MCIPs). A heterogeneously structured CoCrNi-based alloy achieved σy of approximately 2 GPa and εu of approximately 13%. However, this alloy requires complicated processing, including cryo-rolling at 77 K (ref. 19). In addition, in ultra-high-strength HEAs, the reported εu can be largely mediated by Lüders bands propagating from one end of the gauge length to the other. An example is the nominal εu of approximately 16% claimed in an anisotropic (Ni1.5FeCoCr0.5)87.5Al7.5Ti5.0 HEA with a lamellar structure, achieving σy of approximately 2 GPa and ultimate tensile strength σUTS of approximately 2.1 GPa (ref. 20). Another example is the medium-entropy alloy VCoNi, which reached 2 GPa, but its rising stress–strain curve was preceded by Lüders strain4. To bolster strength, one alternative was to involve incoherent B2 precipitates in combination with L12, an example being the FeNiCoAlTaB system. However, its B2 content was far from enough to produce satisfactory strength, obtaining merely σy of approximately 1 GPa and σUTS of approximately 1.4 GPa, although εu reached approximately 20% (ref. 21). In summary, the available HMEAs fall short in surpassing the state-of-the-art steels, and approximately 2-GPa HMEAs with large and truly uniform tensile ductility have yet to be discovered.

A question that naturally arises is how far one can reach towards the upper-right corner of the strength–ductility plot (shown later). The search for suitable HMEAs faces an enormous composition space. Active learning is widely recognized for its efficiency in navigating vast design spaces, but it involves many iterations and complex models to effectively shortlist candidates for experiments22. Our approach incorporates domain-specific knowledge, which narrows down the scope and enhances the performance of the machine learning model (Supplementary Note 1). Eventually, a multi-principal-element alloy with a composition of Fe35Ni29Co21Al12Ta3 was identified. Subsequent post-casting processing (various rolling and heat treatment parameters) achieved our objective. The yield strength–uniform ductility combinations range from 1.5 GPa (31%) to 1.95 GPa (15%), covering a territory previously inaccessible for all bulk alloys. A prominent example, discussed at length below, delivers a σy of 1.75 GPa, σUTS of 2.4 GPa (the corresponding true stress is as high as 3 GPa), a high work hardening rate (WHR, Θ) sustained at higher than 2 GPa and εu of 25%.

Active learning for composition design

The following domain knowledge aided in the selection of composition and processing: (1) Atomic size misfit maximization for pronounced solid solution strengthening—given both a large atomic size mismatch and a large negative mixing enthalpy (Supplementary Table 1) after adding AlTa into the FCC matrix, a high strength is projected for FeNiCoAlTa HEAs23. (2) A very high fraction of strong L12 coherent nanoprecipitates—normally, high-solubility and fast-diffusing solutes (such as Al) favour nanoprecipitates with a large volume fraction9,24. Here we deliberately assembled a high content of Al and L12-promoting Ta solutes into the FeNiCo base alloy to help generate high-volume-fraction coherent L12 nano-MCIPs. The anti-phase boundary energy γAPB of Ta-containing L12 MCIPs, which is higher than that of Ti-containing L12 previously used for strengthening (σy of less than or equal to 1.2 GPa (refs. 17,18)), enhances precipitation strengthening. (3) An appreciable fraction of ductile B2 incoherent microprecipitates at high Al concentrations that contributes to strengthening on top of the L12 nanoprecipitates—compared with the traditional hard/brittle intermetallic inclusions, the chemically complex MCIPs with several components show lower chemical ordering energy (Extended Data Fig. 1) and γAPB, which is expected to facilitate dislocation slip and enhance plasticity1,2,3,18. These B2 micro-MCIPs could accommodate ample dislocation activities with no worries of (local) stress concentrations and accumulate dislocations inside to promote WHR for enhanced uniform elongation.

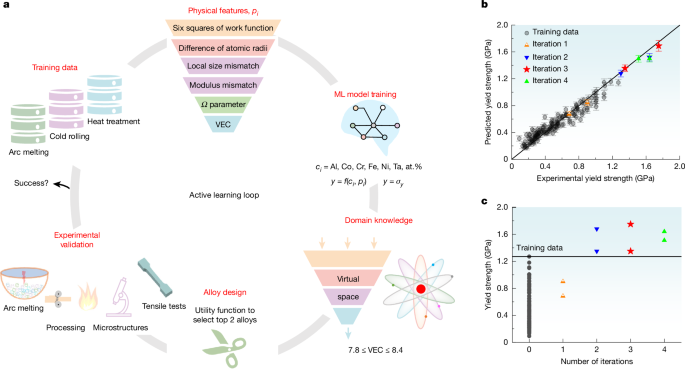

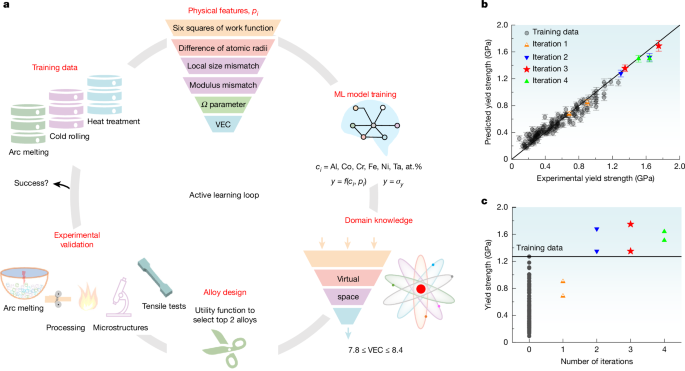

Figure 1a shows the iterative loop of active learning aimed at optimizing alloy compositions for high strength, starting from a dataset comprising 140 FCC HEAs within the AlCoCrFeNiTa alloy system, with the measured σy and elongation to fracture, εf (Supplementary Fig. 2). All alloys reported in the literature or produced in our laboratory were prepared through arc melting, followed by homogenization, cold rolling and heat treatment. From a pool of 20 physical features (Supplementary Table 2), as shown in Fig. 1a, six were selected (Supplementary Fig. 3a) as the domain knowledge input for the machine learning surrogate model aimed at reducing model complexity, given that the model performance does not significantly improve with extra features. The detailed machine learning model about target alloy design is presented in Supplementary Note 1. Figure 1b compares all four iterations with the training data; six of the eight newly synthesized alloys showed higher σy. Most data points were very close to or even located right on the diagonal line (Fig. 1b), further verifying the high reliability and robustness of our machine learning model. Figure 1c shows the relationship between the improvement in σy with increasing iteration, and the desired alloy was achieved after the third iteration. The Fe35Ni29Co21Al12Ta3 alloy, hereafter referred to as the HEA05 alloy, had the highest σy among all compositions (Supplementary Table 4).

a, The domain knowledge-based active learning loop consists of six steps: (1) training data collection; (2) physical descriptor inclusion; (3) machine learning (ML) model training; (4) virtual space narrowed through domain knowledge; (5) alloy design by utility function; and (6) experimental validation and feedback. b, Plot of predicted σy versus experimental σy of the eight newly synthesized alloys from the four iterations, as well as the training data, showing the high reliability and robustness of the present ML model. c, Experimental σy versus the number of iterations, showing the optimized σy of the HEA05 alloy at the third iteration.

Dual-precipitate microstructure

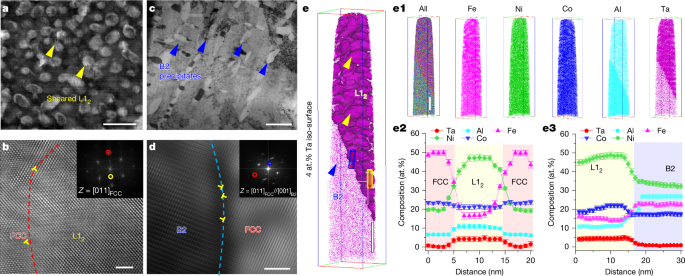

We now focus on the best-performing HEA05, with reference to its base alloy, A0 (Fe35Ni29Co21)100Al0Ta0 (normalized to Fe41Ni34Co25), the Al-alloying-only (Fe35Ni29Co21)88Al12 and the Ta-alloying-only (Fe35Ni29Co21)97Ta3. HEA05 processed at 750 °C for 1 h of ageing was used as a representative. Although machine learning directed us to this composition, the microstructures inside were essential for the properties. By highly alloying with both Al and Ta, we successfully introduced densely dispersed L12 coherent nano-MCIPs and low modulus-yet-hard deformable B2 incoherent micro-MCIPs (Extended Data Fig. 2, Supplementary Fig. 6 and Supplementary Note 2) into the FCC matrix having randomly oriented equiaxed grains with the average size (d) of approximately 7.6 µm (Fig. 2 and Extended Data Fig. 3). As shown in Fig. 2a, near-spherical L12 nano-MCIPs with d of approximately 15 ± 3 nm were uniformly distributed inside the grain interiors with a volume fraction as high as 66.6 ± 2.3%, as measured using small-angle X-ray scattering (SAXS; Extended Data Fig. 4). The B2 micro-MCIPs formed during the casting process have a typical dimension of 350 ± 70 nm, with a length-to-width aspect ratio averaging approximately 3.1 (Extended Data Fig. 3) and a volume fraction of 15 ± 2%, residing between FCC grains. The interfacial mismatch strain can be determined from the wide-angle X-ray scattering (WAXS) patterns (Extended Data Fig. 5) to be approximately 0.24 ± 0.03% and 22.8 ± 0.01% for the L12/FCC and B2/FCC interfaces, respectively. Apparently, Ta, Al and Ni elements primarily partitioned to the L12 nano-MCIPs and Al and Ni elements to the B2 micro-MCIPs, whereas Fe and Co were largely depleted from both types of precipitates (Fig. 2e(1–3), Extended Data Fig. 6, Supplementary Fig. 7 and Supplementary Note 3). The results are summarized in Supplementary Table 5.

The alloy was aged at 750 °C for 1 h. a, Scanning transmission electron microscopy (STEM) image of L12 precipitates in the FCC matrix after tensile deformation to 5% strain, with the corresponding selected area electron diffraction (SAED; inset). Two examples of dislocation-sheared L12 precipitates are marked using yellow arrows. b, High-resolution transmission electron microscopy image showing the FCC/L12 interfaces (with dislocations after 5% strain) and the corresponding fast Fourier transform pattern (inset). c, STEM image of B2 precipitates located close to one another in the FCC matrix. Blue arrows indicate several examples of B2 precipitates. d, High-resolution transmission electron microscopy image showing the FCC/B2 interfaces having Kurdjumov–Sachs relationship: (111)FCC//(110)B2 and [110]FCC//[111]B2 at 5% strain, with the corresponding SAED (inset). e, Atom probe tomography (APT) results of HEA05 alloys with 4 at.% Ta iso-concentration surface: respective elemental distribution of FCC, L12 and B2 phases (e1); composition profile across FCC–L12 (e2); and composition profile across L12 and B2 phases (e3). Scale bars, 50 nm (a,e,e(1)), 2 nm (b,d), 500 nm (c).

Extraordinary mechanical properties

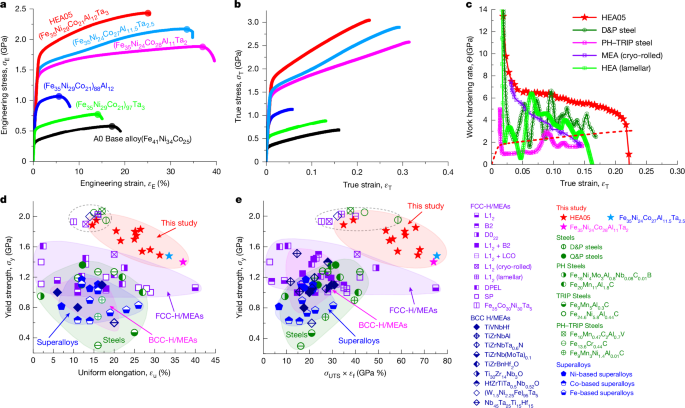

The highly heterogeneous microstructure consisting of dual precipitates in the FCC concentrated solid solution (‘matrix’) endows the HEA05 Fe35Ni29Co21Al12Ta3 alloys with extraordinary mechanical properties, as shown in Fig. 3a,b. For comparison, we started from single-element alloying, which increased the strength σy from approximately 300 MPa for the A0 base alloy to approximately 500 MPa for 3 at.% Ta and to approximately 800 MPa for 12 at.% Al. Nevertheless, the latter two alloys exhibited notably reduced ductility, particularly εu. By contrast, both εu (25%) and εf of the (750 °C for 1 h) HEA05 alloy were far superior, simultaneously with a drastically elevated σy (1.75 GPa) 6-fold over the A0 base alloy. Yet, it showed an even higher WHR at the same time, enabling a notably enhanced tensile elongation (Fig. 3a and Extended Data Fig. 7). To further testify the superiority of HEA05, another two FeNiCoAlTa alloys were prepared with somewhat reduced Al and Ta concentrations, that is, Fe35Ni24Co28Al11Ta2 and Fe35Ni24Co27Al11.5Ta2.5 alloys, containing less B2 volume fractions at approximately 8% and 11%, respectively (Fig. 3 and Supplementary Fig. 8). They have lower σy but larger εu. Notably, we tuned the processing condition of our HEA05 alloy at its fixed composition and observed a range of tensile stress–strain curves (compiled in Extended Data Fig. 7), all showing significant strain hardening and large εu at high σy between 1.5 and 1.95 GPa. As summarized in Fig. 3d,e), the systematic data (elliptical area covering the data points represented by red stars) demonstrate the tunability and trend of performance, ranging from 1.5 GPa (31%) to 1.95 GPa (15%). Taken as a group, the entire ellipse presented strength–ductility combinations superior to all previous alloys.

a, Engineering stress–strain curve. b, True stress–strain curve of the HEA05 alloy (750 °C for 1 h) compared with its base alloy A0 (Fe41Ni34Co25), with (Fe35Ni29Co21)88Al12, (Fe35Ni29Co21)97Ta3, Fe35Ni24Co27Al11.5Ta2.5 (light blue) and Fe35Ni24Co28Al11Ta2 (pink). c, Comparison of WHRs Θ with some 2-GPa steels2,3 and 2-GPa HMEAs19,20. (The alloys inside the light purple colours in d and e have serrated WHR curves.) d, Comparison with representatives of other high-strength alloy categories in yield strength and uniform elongation space. Our new alloys in the oval area (for the tensile curves of HEA05 processed under different conditions, see Extended Data Fig. 7 and Extended Data Table 1) clearly stood out, outperforming all previous alloys. e, Strength σy versus the product of σUTS and εf of HEA05 alloys, showing that the latter also outranked other ultra-high-strength FCC HEAs strengthened by L12 (refs. 18,27,28,42,50); B2 (refs. 15,21,30); D022 (ref. 34); L12 and B2 (refs. 14,16,31,32,33); L12 and LCO4; cryo-rolled HEAs19; lamellar HEAs20; DPEL29,35; single phase (SP)5,36,37,38; BCC-M/HEAs39,40,41; Fe-based, Co-based and Ni-based superalloys12; D&P steels2; quenched and partitioned (Q&P) steels11,43; precipitation hardened (PH) steels25; TRIP steels25; and PH–TRIP steels25.

This oval-shaped new territory is centred around the impressive point reported in Fig. 3a, which shows a σy = 1,750 ± 50 MPa, σUTS = 2,403 ± 46 MPa, stable WHR Θ higher than 2 GPa across the entire strain range and εu = 25 ± 1.5%. This combination stood out when compared with the best of bulk steels1,2,3,10,25 (Fig. 3c–e). The simultaneous ultra-high σy and large ɛu also set this HEA05 alloy apart (comparisons in Fig. 3d) from all previously reported precipitation-strengthened HEAs15,16,18,26,27,28,29,30,31,32,33,34, dual-phase eutectic lamellae (DPEL) HEAs16,29,35,36, single-phase HEAs5,36,37,38 and the best-performing BCC-HMEAs39,40,41, which have either lower strength or lower ductility (or both lower).

Figure 3b shows the tensile true stress–strain curves, showing that the HEA05 alloy can reach true stress as high as approximately 3 GPa. This is because of its superior WHR, clearly above the base A0, (Fe35Ni29Co21)88Al12 and (Fe35Ni29Co21)97Ta3 alloys. The work hardening capability, in terms of the strength difference σUTS − σy = 650 MPa or the yield ratio σy/σUTS = 0.73, is extraordinary. Finally, the HEA05 alloys (red stars) also have a high value of the product σUTS × εf (for example, 60 GPa %), outranking other high-performance alloys (Fig. 3e; the way to go is in the direction pointing towards the upper-right corner), including precipitation-strengthened L12 (refs. 18,27,28,42), B2 (refs. 15,21,30), D022 (ref. 34), L12 and B2 (refs. 14,16,31,32,33), L12 and LCO4. Their performance also surpassed that of cryo-rolled HEAs19; lamellar HEAs20; DPEL29,35; single phase5,36,37,38; Fe-based, Co-based and Ni-based superalloys12; D&P steels2; quenched and partitioned steels11,43; precipitation hardened steels25; transformation-induced plasticity (TRIP) steels25; and precipitation hardened–transformation-induced plasticity (PH–TRIP) steels25.

Note that to avoid violating the Considère instability criterion to maintain uniform tensile elongation, the WHR must always remain higher than the flow stress in the tensile test. In Fig. 3c, the previous approximately 2-GPa HEAs and steels that came close to HEA05 in WHR all exhibited stress serrations and plunges in the WHR curve to below the true stress–strain curve of HEA05, as seen superimposed using a dashed curve. Thus, these alloys suffer from unstable plastic flow and hence are placed in the dashed circle in Fig. 3d,e. In other words, they would succumb to strain localization at some point soon after yielding, and HEA05 is the only alloy with consistently stable WHRs Θ higher than 2 GPa across a wide strain range. Similarly, a high WHR was observed for HEA05 processed under other conditions (Extended Data Fig. 7c). Notably, the impressive Θ and εu ensured high processibility in shaping/forming and a large safety margin against fracture for our high-strength alloys, which is highly desirable for engineering applications.

In what follows, we illustrate the underlying mechanisms for the high strength and extraordinary work hardening capability. Coherent strengthening by the L12-type precipitates has been extensively investigated in Ni-based superalloys and HMEAs. The HEA05 combines, in one alloy, the following three desirable attributes: (1) the coherent L12 nanoprecipitates are effectively strengthened using Ta alloying, and their volume fraction is close to the highest ever for superalloys (such as René N5); (2) with our significant Al addition, the B2 phase fraction is also rather high among the reported HEAs; and (3) the MCIPs in our alloys contain a high level of extra elements and are, therefore, far more ductile and strain-hardenable than traditional intermetallic compounds44,45 (further discussion later).

First, we discuss the ultra-high yield strength. This results from the densely populated L12 nano-MCIPs and B2 micro-MCIPs in an effectively solid solution-strengthened FCC matrix (Supplementary Fig. 9 and Supplementary Note 4). The volume fraction of precipitates in our alloy was extraordinarily high for both L12 (approximately 67%) and B2 (approximately 15%). The precipitate hardening in the coherent FCC/L12 case is mainly attributable to the γAPB cost for the step creation by the interface-crossing dislocation, particularly for the Ta-alloyed L12 nano-MCIPs that have a higher γAPB than the base L12 and Ti-alloyed ones (Extended Data Fig. 1). In the FCC/B2 case, the incoherent interfaces are strong traps for glide dislocations and thus are effective barriers for slip transmission. As expected, the calculation of yield strength (Supplementary Note 5) revealed that coherent L12 nano-MCIPs dominated the σy enhancement (approximately 859 MPa), followed by incoherent B2 micro-MCIPs (approximately 351 MPa), lattice friction (approximately 277 MPa), stored dislocations (approximately 206 MPa) and grain boundaries (approximately 167 MPa).

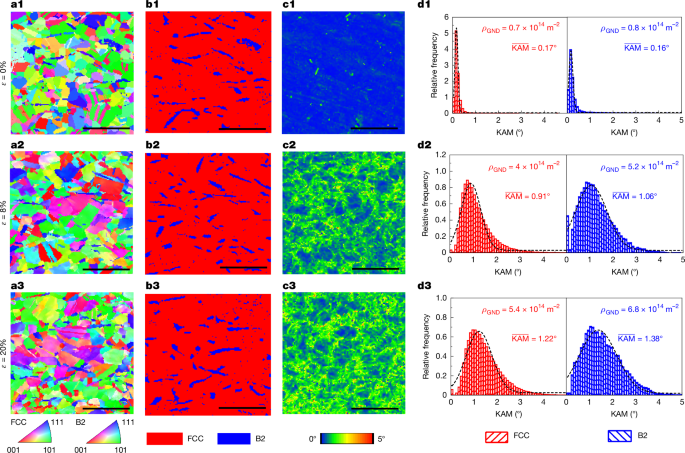

Next, we explain the extraordinary work hardening that sustains the large εu upon uniaxial tensile loading, as shown in Fig. 3. The dislocation densities of HEA05 at different deformation stages were monitored using a transmission electron microscope (TEM) (Fig. 2a,b and Extended Data Fig. 8), transmission Kikuchi diffraction (TKD; Extended Data Fig. 9) and electron backscatter diffraction (EBSD; Fig. 4). After 5% strain, the L12 nano-MCIPs were sheared by gliding dislocations, as shown in Fig. 2. (Some were observed at the FCC/L12 and FCC/B2 interfaces). Figure 4c(1–3),d(1–3) shows that as the strain increased from 8% to 20%, the kernel average misorientation (KAM) value of L12 in the FCC regions increased slightly from 0.91° to 1.22°, whereas that of B2-MCIPs increased from 1.06° to 1.38°. This indicates that the geometrically necessary dislocation (GND, ρGND) density increased with increasing plastic strains (Supplementary Note 6). The GND density ratio of the L12-dominant FCC to the B2 phase monotonically decreased from 0.87 at 0% strain to 0.79 at 20% strain (Fig. 4d(1–3)). The TKD results also revealed that both phases contained abundant GNDs with KAM less than 2° (Extended Data Fig. 9). TEM also revealed abundant dislocations accumulated inside B2-MICPs (Extended Data Fig. 8), indicating their heavy involvement in co-deformation. This is different from the traditional hard B2 phase, which often shows brittle fracture at low strain levels10. The high ρGND accumulated in B2 during tensile straining (note that in Fig. 4d(3), ρGND in B2-MCIPs is higher than that in the L12 + FCC; Extended Data Figs. 8 and 9) led to strain hardening along with tensile straining. This emphasizes that these B2-MCIPs are not only shearable by dislocations but also amenable to dislocation multiplication inside. This striking ductile behaviour of B2 can be attributed to its significantly depressed chemical ordering energy (Extended Data Fig. 1) and reduction in dislocation strain energy (caused by the FCC–B2 modulus mismatch when the dislocations transmitted across their incoherent interfaces46,47; Supplementary Note 2). Although the binary NiAl B2 phase has a high γAPB of approximately 671 mJ m−2, alloying (particularly with Ta) into B2 reduces this γAPB by approximately 30% (ref. 48), rendering the intermetallic deformable through dislocations and yet still strong. Meanwhile, the strength differences between the L12, B2 and FCC matrices would promote non-homogeneous deformation, adding GNDs that enhance WHRs. This mechanism has recently been recast as hetero-deformation-induced (HDI) hardening (Supplementary Fig. 10)49. The unusually heterogeneous microstructure in our complex alloy, with hierarchical inhomogeneities including interfaces on ultrafine to nanometre scales, would give rise to extra strain hardening39. Given our extraordinarily high densities of precipitates, dislocation trapping/tangling, reactions and multiplication are expected to be more effective than those in previous alloys. Furthermore, the interphase interfaces serve as sustainable dislocation sources at high stress.

In conclusion, we developed a high-entropy alloy (Fe35Ni29Co21Al12Ta3), assisted by domain knowledge-guided machine learning. The new alloy has a highly heterogeneous microstructure that comprises unusually dense MCIPs in an HEA FCC matrix, including both coherent L12 nanoprecipitates and incoherent lower-modulus-yet-hard B2 particles, which not only effectively impart strengthening, but also profusely interact with dislocations to sustain a high WHR above 2 GPa to large true strains. The appreciable volume fraction of the ductile B2-MCIPs with effective dislocation accumulation adds room for strain hardening. Our HEAs, with a yield strength of 2 GPa, rival super steels and yet have excellent uniform ductility towards the level of elemental metals, thus go beyond what the best bulk steels have to offer. Our alloy design strategy, through active learning-guided heavy alloying and extraordinary amounts of precipitates, including ductile (and work-hardenable) second phase, is expected to be applicable to other alloy systems. This pushes the envelope of mechanical properties (towards the upper-right corner of the strength–ductility space) and expands the material selection repertoire for demanding applications.

Methods

Machine learning model for alloy design

Practically, it is impossible to search through the approximately 1049potential alloy variants by means of trial and error. To pave the way for landing effective HEAs that outperform advanced steels, our strategy is to speed up the search by integrating active learning, a subfield of machine learning, with domain expert knowledge in microstructure design. Although active learning has been extensively used to optimize the chemical compositions of new alloys, its application in the design of microstructures has been limited by the scarcity of data available for microstructural information. To overcome this obstacle, our active learning loop was coupled with domain knowledge by customizing the principal elements and their composition ranges after each iteration, followed by the design of a triple-phase structure through post-processing once the chemical composition was optimized. The selection of elements, integration of physical features and filtering to focus on FCC alloys through the valence electron concentration all contribute to the effectiveness of our active learning process. The detailed machine learning model of the target alloy design is presented in Supplementary Note 1.

Fabrication of materials

Alloy ingots with compositions predicted from the machine learning model were prepared using the arc melting technique under a high-purity argon atmosphere. The purity of each element was at least 99.95%, and the ingot was remelted five times to ensure chemical homogeneity. The as-cast ingots were then subjected to homogenization treatment at 1,250 °C for 2 h, followed by water quenching. Subsequently, the homogenized samples were cold-rolled to a sheet with a thickness reduction of approximately 81%, recrystallized at 1,100 °C for approximately 1 min and finally aged at 750 °C for 1 h (Supplementary Fig. 5).

Microstructural characterization

The microstructures of the fabricated alloys were characterized using X-ray diffraction (XRD; Bruker D8 DISCOVER powder), TEM (JEOL JEM-2100F), scanning electron microscope (SEM; ZEISS Super 55) and EBSD installed on the equippment with energy dispersive spectroscopy. EBSD analysis along the normal direction with a step size of 0.5 μm was performed to estimate the mean grain size (d), crystallographic orientations and KAM. The TKD technique was also performed on the alloys before and after deformation using a ZEISS ULTRA plus Field Emission Gun Scanning Electron Microscope operating at 30 kV, equipped with an Oxford Instruments Channel 5 EBSD system and Nordlys-S EBSD detector. The step size used for data collection was 20 nm. All TKD scans were taken in the normal direction, parallel to the z axis. The TKD samples were prepared for electron transparency (about 100 nm) through electropolishing (Struers TenuPol-5 Twin Jet Electro-polisher) in an electrolyte solution containing 25% nitric acid and 75% methanol at −10 °C.

To analyse the distribution of elements and the sizes of nanoprecipitates in our designed FeNiCoAlTa alloys, needle-shaped specimens required for APT were fabricated by lift-outs and annular milling in an FEI Scios focused ion beam/scanning electron microscope. The APT experiments were performed on a CAMECA local electrode atom probe (LEAP 4000X Si) under high vacuum (less than 4 × 10−11 torr) at 50 K. The Integrated Visualization & Analysis Software v.3.6.8 was used for the three-dimensional reconstructions and compositional analyses of the APT data. To determine the composition of the L12 nanoprecipitates, all of which had sizes less than or equal to 22 nm, the APT data were sorted for various sizes (three to five measurements at each size), and an alloy average was extracted from the 27 data points (for example, for Ta in Supplementary Fig. 11).

To obtain the precipitate volume fraction at the macroscale, synchrotron-based SAXS was conducted on the BL16B1 beamline at the Shanghai Synchrotron Radiation Facility. The sample was electrical discharge machined and wet polished to a thickness of 15 μm. Two-dimensional (2D) SAXS patterns were collected using a PILATUS 2M Detector System (1,475 × 1,679 pixels with 172 × 172 μm2 pixel−1), and the X-ray energy was 16 ± 1.6 keV with a beam size of 500 × 500 μm2. The exposure time was 200 s. The sample-to-detector distance was calibrated to be 1,955 mm using a standard sample of silver behenate (AgBH). Background scattering from the air and sample chamber was recorded and used to correct the 2D SAXS patterns of the sample. The 2D patterns were exported and converted into one-dimensional diffraction intensity profiles as a function of the wavevector Q using the FIT2D software (v.18; ref. 51). The precipitate size distributions were obtained by fitting the Schulz–Zimm, gamma and generalized exponential distributions using the SASfit program52. The precipitate size and volume fraction were calculated from local monodisperse approximation53, a common approximation suitable for a polydisperse system with relatively large polydispersity and high concentrations. The L12 volume fraction was taken as the average of the three results from these three distributions.

Tensile testing and load–unload–reload testing

To determine the strength and ductility of the designed alloys, uniaxial tensile tests were conducted at room temperature using an Instron 1195 and SUNS-UTM5105-G testing machine at a tensile strain rate of 1 × 10−3 s−1 using a mechanical extensometer. Flat dog bone-shaped tensile specimens with a thickness of 1.5 mm and a gauge section of 15 × 4.5 mm were machined from the centre region of the plates along the rolling direction to avoid the surface effect on the microstructure. At least three samples were tested to ensure repeatability of our testing. The tensile properties, including yield strength (σy), ultimate tensile strength (σUTS), uniform elongation (εu) and elongation to fracture (εf), were recorded. HDI strengthening can be experimentally measured through the load–unload–reload test. The analysis of the load–unload–reload behaviour of our HEA05 alloy is shown in Supplementary Fig. 10a, and the HDI stress σHDI was quantitatively evaluated following previous studies5,36,37,38. It seems that the stress σHDI in the HEA05 alloys increased with increasing strain (Supplementary Fig. 10b).

Data availability

All data supporting the findings of this study are available in the paper and the Supplementary Information. The dataset used for training the machine learning model in this study are available at GitHub (https://github.com/diegoxue/Active-learning-for-Record-Setting-Alloy).

References

Jiang, S. et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 544, 460–464 (2017).

Li, Y. et al. Ductile 2-GPa steels with hierarchical substructure. Science 379, 168–173 (2023).

He, B. et al. High dislocation density-induced large ductility in deformed and partitioned steels. Science 357, 1029–1032 (2017).

Xu, B. et al. Harnessing instability for work hardening in multi-principal element alloys. Nat. Mater. 23, 755–761 (2024).

Ming, K., Bi, X. & Wang, J. Strength and ductility of CrFeCoNiMo alloy with hierarchical microstructures. Int. J. Plast. 113, 255–268 (2019).

Yang, Y. et al. Bifunctional nanoprecipitates strengthen and ductilize a medium-entropy alloy. Nature 595, 245–249 (2021).

Zhang, B. B., Tang, Y. G., Mei, Q. S., Li, X. Y. & Lu, K. Inhibiting creep in nanograined alloys with stable grain boundary networks. Science 378, 659–663 (2022).

Cheng, Z., Zhou, H., Lu, Q., Gao, H. & Lu, L. Extra strengthening and work hardening in gradient nanotwinned metals. Science 362, eaau1925 (2018).

Sun, W. et al. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity. Science 363, 972–975 (2019).

Kim, S.-H., Kim, H. & Kim, N. J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 518, 77–79 (2015).

Seo, E. J., Cho, L., Estrin, Y. & De Cooman, B. C. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 113, 124–139 (2016).

Geddes, B., Leon, H. & Huang, X. Superalloys: Alloying and Performance (ASM International, 2010).

Wu, X. et al. Unveiling the Re effect in Ni-based single crystal superalloys. Nat. Commun. 11, 389 (2020).

Gwalani, B. et al. Influence of ordered L12 precipitation on strain-rate dependent mechanical behavior in a eutectic high entropy alloy. Sci. Rep. 9, 6371 (2019).

Zhang, D., Zhang, J., Kuang, J., Liu, G. & Sun, J. The B2 phase-driven microstructural heterogeneities and twinning enable ultrahigh cryogenic strength and large ductility in NiCoCr-based medium-entropy alloy. Acta Mater. 233, 117981 (2022).

Bhattacharjee, T. et al. Simultaneous strength-ductility enhancement of a nano-lamellar AlCoCrFeNi2.1 eutectic high entropy alloy by cryo-rolling and annealing. Sci. Rep. 8, 3276 (2018).

Chen, E. et al. Modeling antiphase boundary energies of Ni3Al-based alloys using automated density functional theory and machine learning. NPJ Comput. Mater. 8, 80 (2022).

Yang, T. et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 362, 933–937 (2018).

Du, X. et al. Dual heterogeneous structures lead to ultrahigh strength and uniform ductility in a Co-Cr-Ni medium-entropy alloy. Nat. Commun. 11, 2390 (2020).

Fan, L. et al. Ultrahigh strength and ductility in newly developed materials with coherent nanolamellar architectures. Nat. Commun. 11, 6240 (2020).

Zhang, C. et al. Strong and ductile FeNiCoAl-based high-entropy alloys for cryogenic to elevated temperature multifunctional applications. Acta Mater. 242, 118449 (2023).

Rao, Z. et al. Machine learning-enabled high-entropy alloy discovery. Science 378, 78–85 (2022).

Zhang, D. D., Zhang, J. Y., Kuang, J., Liu, G. & Sun, J. Superior strength-ductility synergy and strain hardenability of Al/Ta co-doped NiCoCr twinned medium entropy alloy for cryogenic applications. Acta Mater. 220, 117288 (2021).

Xue, H. et al. Highly stable coherent nanoprecipitates via diffusion-dominated solute uptake and interstitial ordering. Nat. Mater. 22, 434–441 (2023).

Ma, E. & Wu, X. Tailoring heterogeneities in high-entropy alloys to promote strength–ductility synergy. Nat. Commun. 10, 5623 (2019).

Liang, Y.-J. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys. Nat. Commun. 9, 4063 (2018).

He, J. et al. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 102, 187–196 (2016).

Wu, S. et al. A precipitation strengthened high entropy alloy with high (Al+Ti) content for laser powder bed fusion: synergizing in trinsic hot cracking resistance and ultrahigh strength. Acta Mater. 258, 119193 (2023).

Shi, P. et al. Enhanced strength–ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae. Nat. Commun. 10, 489 (2019).

Xiong, T., Zheng, S., Pang, J. & Ma, X. High-strength and high-ductility AlCoCrFeNi2.1 eutectic high-entropy alloy achieved via precipitation strengthening in a heterogeneous structure. Scr. Mater. 186, 336–340 (2020).

Zhang, C. et al. Aged metastable high-entropy alloys with heterogeneous lamella structure for superior strength-ductility synergy. Acta Mater. 199, 602–612 (2020).

Reddy, S. et al. Engineering heterogeneous microstructure by severe warm-rolling for enhancing strength-ductility synergy in eutectic high entropy alloys. Mater. Sci. Eng. A 764, 138226 (2019).

Yang, H. et al. Nanophase precipitation and strengthening in a dual-phase Al0.5CoCrFeNi high-entropy alloy. J. Mater. Sci. Technol. 72, 1–7 (2021).

He, F. et al. Design of D022 superlattice with superior strengthening effect in high entropy alloys. Acta Mater. 167, 275–286 (2019).

Wani, I. et al. Ultrafine-grained AlCoCrFeNi2.1 eutectic high-entropy alloy. Mater. Res. Lett. 4, 174–179 (2016).

Slone, C., Miao, J., George, E. P. & Mills, M. J. Achieving ultra-high strength and ductility in equiatomic CrCoNi with partially recrystallized microstructures. Acta Mater. 165, 496–507 (2019).

Yang, M. et al. Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength. Proc. Natl Acad. Sci. USA 115, 7224–7229 (2018).

Wu, S. et al. Enhancement of strength-ductility trade-off in a high-entropy alloy through a heterogeneous structure. Acta Mater. 165, 444–458 (2019).

Ma, E. & Liu, C. Chemical inhomogeneities in high-entropy alloys help mitigate the strength-ductility trade-off. Prog. Mater Sci. 143, 101252 (2024).

Li, T. et al. Ultra-strong tungsten refractory high-entropy alloy via stepwise controllable coherent nanoprecipitations. Nat. Commun. 14, 3006 (2023).

Cook, D. H. et al. Kink bands promote exceptional fracture resistance in a NbTaTiHf refractory medium-entropy alloy. Science 384, 178–184 (2024).

Han, L. et al. A mechanically strong and ductile soft magnet with extremely low coercivity. Nature 608, 310–316 (2022).

Zhang, K., Liu, P., Li, W., Guo, Z. & Rong, Y. Ultrahigh strength-ductility steel treated by a novel quenching–partitioning–tempering process. Mater. Sci. Eng. A 619, 205–211 (2014).

Chiba, A., Hanada, S. & Watanabe, S. Improvement in ductility of Ni3Al by γ former doping. Mater. Sci. Eng. A 152, 108–113 (1992).

Feng, R. et al. Enhancing fatigue life by ductile-transformable multicomponent B2 precipitates in a high-entropy alloy. Nat. Commun. 12, 3588 (2021).

Xiong, T. et al. Faceted Kurdjumov-Sachs interface-induced slip continuity in the eutectic high-entropy alloy, AlCoCrFeNi2.1. J. Mater. Sci. Technol. 65, 216–227 (2021).

Dong, L. et al. Borrowed dislocations for ductility in ceramics. Science 385, 422–427 (2024).

Lü, B. L., Chen, G. Q., Qu, S., Su, H. & Zhou, W. L. Effect of alloying elements on <1 1 1> dislocation in NiAl: a first-principles study. Physica B 417, 9–12 (2013).

Yang, M., Pan, Y., Yuan, F., Zhu, Y. & Wu, X. Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 4, 145–151 (2016).

Han, L. et al. Two-gigapascal-strong ductile soft magnets. Nat. Commun. 15, 10119 (2024).

Hammersley, A. FIT2D: a multi-purpose data reduction, analysis and visualization program. J. Appl. Crystallogr. 49, 646–652 (2016).

Breßler, I., Kohlbrecher, J. & Thünemann, A. F. SASfit: a tool for small-angle scattering data analysis using a library of analytical expressions. J. Appl. Crystallogr. 48, 1587–1598 (2015).

Pedersen, J. S. Determination of size distribution from small-angle scattering data for systems with effective hard-sphere interactions. J. Appl. Crystallogr. 27, 595–608 (1994).

Tucker, M. G., Dove, M. T. & Keen, D. A. Application of the reverse Monte Carlo method to crystalline materials. J. Appl. Crystallogr. 34, 630–638 (2001).

Dove, M. T., Tucker, M. G. & Keen, D. A. Neutron total-scattering method: simultaneous determination of long-range and short-range order in disordered materials. Eur. J. Mineral. 14, 331–348 (2002).

Tucker, M. G., Keen, D. A., Dove, M. T., Goodwin, A. L. & Hui, Q. RMCProfile: reverse Monte Carlo for polycrystalline materials. J. Phys. Condens. Matter 19, 335218 (2007).

Hamilton, W. C. Significance tests on the crystallographic R factor. Acta Crystallogr. 18, 502–510 (1965).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (grant nos. 52441407, 52431006, 92163201, U23A6013, 92360301 and U2330203), 111 Project of China (B25007), Shaanxi Province Innovation Team Project (2024RS-CXTD-58) and Fundamental Research Funds for the Central Universities (xtr062024006). E.M. acknowledges the support by the National Natural Science Foundation of China (grant no. 52231001). We would like to thank J. Li, Z. J. Ren, S. W. Guo and Y. H. Li for their kind help with the microstructural characterization of materials. Synchrotron-based SAXS was conducted on the BL16B1 beamline at the Shanghai Synchrotron Radiation Facility, and we acknowledge S. M. He and X. R. Miao for their help with the SAXS experiments.

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Dieter Isheim and Ying Yang for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 The formation energy and chemical ordering energy for the L12 and B2 phases.

a, and b, show the ordering crystallographic structure and site occupancy of the L12 and B2, respectively, used in this work generated by an SQS method via RMC profile54,55,56, with the compositions involved in this work. c, The formation energy of the chemically ordered vs random-solution structures. d, The ordering energy for the multi-component L12 and B2 phases (with Ta or Ti), compared to traditional binary Ni-Al L12 and B2 phases. Note: We built three different models by changing the placement of atoms in a unit cell, and we calculated the average value of formation and ordering energy. The results from the three parallel samples are consistent, as reflected by the small error bars in the figure.

Extended Data Fig. 2 Tensile properties and microstructure of B2-dominant alloys.

a, Tensile stress-strain curves of as-casted and homogenized B2-dominated alloys with varying Ta concentrations, i.e., 0 at.% (for Ta0 alloys) and 0.8 at.% (for Ta0.8 alloys) to check the effect of Ta on the B2 phase ductility, b, Table of tensile properties of coarse-grained B2 dominant alloys. Increasing the Ta concentration from 0 at.% to 0.8 at.% in the B2 phase, the uniform elongation (UE) is almost tripled from 5.5% to 14.1% for the duplex (FCC + B2) alloys, which shows a strong tendency of Ta in promoting the ductility of the B2 phase in our alloy. c, The SEM image of the Ta0 alloy at homogenized stage (1200 °C-2hr), d, The Ta0.8 alloy at homogenized stage (1200 °C-2hr), showing B2 dominant regions with a small amount of the FCC phase with a grain size of ~400 µm. Reducing grain sizes to ~80 μm by hot rolling, the yield strength (YS) and ultimate tensile strength (UTS) increase to ~1.1 and ~1.66 GPa, respectively. The EBSD IPF map (e), phase map (f), KAM (g), and GND (h) of the Ta0.8 alloy, hot rolled (HR-70%) with 8% strains, revealing the ductile B2 MCIPs are capable of accumulating dislocations during deformation to sustain a high work hardening rate.

Extended Data Fig. 3 The distribution of B2 precipitates and the grain size-distribution of HEA05 alloys after 750 °C-1hr aging.

a, Overall morphology of B2 in a typical SEM image, b, The STEM image of B2 precipitates in the FCC/L12 matrix at 750 °C-1hr aging, c, The diameter of B2 precipitates, and d, The aspect ratio (length/width) of B2 precipitates, e, f, The IPF image of HEA05 alloys with the grain size distribution.

Extended Data Fig. 4 Small-angle X-ray scattering (SAXS) was used to measure the L12 fraction.

a, Experimentally obtained two-dimensional SAXS spectra, b, Simulated two-dimensional SAXS spectra, simulation is done using sasView software, c, SASfit plot to measure the volume fraction of the L12 nanoprecipitates in the HEA05 alloy. SAXS was used to measure the L12 fraction. SAXS has a wavelength of 0.775 Å, energy ~16 KeV, and an exposure time of 200 s, and the sample to detector distance was ~2 m. The precipitate size distributions were obtained by a fit of the Schultz-Zimm distribution, Gamma distribution, and Generalized exponential distribution (GEX) using the SASfit program52. The precipitate size and volume fraction were calculated from a local monodisperse approximation fit with a sticky hard-sphere interaction potential53. d, The L12 volume fraction by three fitting along with the radius of particle and uncertainty, and Rw. We use the Rw value to judge the goodness of fitting for uncertainty. If Rw < 0.1, the function prediction is a believable value52,57, as shown in Extended Data Fig. 4c. The average L12 volume fraction from three distributions is fV = 66.6 ± 2.3 % (Extended Data Fig. 4d), where the error bar is the standard error determined from the 3 data points.

Extended Data Fig. 5 The wide-angle X-ray scattering (WAXS) patterns of HEA05 alloy and XRD patterns of its derivative alloys.

a, The XRD graphs of our HEA05 base alloys A0 (Fe35Ni29Co21), (Fe35Ni29Co21)88Al12, and (Fe35Ni29Co21)97Ta3. b, The wide-angle X-ray scattering (WAXS) graph of the HEA05 alloy. c, The Gaussian fitting of deconvolution of (331) diffraction peak to calculate the lattice constant of FCC/L12 and respective interfacial mismatch strain, d, The Gaussian peak fitting to calculate the FCC/B2 lattice constant and respective interfacial mismatch strain via the formula: \({\delta }=2({{\rm{a}}}^{{\rm{p}}}-{{\rm{a}}}^{{\rm{m}}})/({{\rm{a}}}^{{\rm{p}}}+{{\rm{a}}}^{{\rm{m}}})\), where ap and am are the lattice parameters of the precipitate and the matrix, respectively.

Extended Data Fig. 6 Elemental partitioning behavior.

Elemental partitioning coefficient for the FCC matrix and L12 nanoprecipitates in the HEA05 alloys aged at 750 °C-1hr, obtained from APT results.

Extended Data Fig. 7 Tensile properties of our new alloys.

a, Engineering stress-strain curves, and b, True stress-strain curves, of HEA05 after different processing, in terms of different cold rolling (CR) thickness reduction percentage (%), recrystallization (Rx) time (at 1100 °C), and aging temperature and time. Two additional alloys with compositions similar to HEA05 have been included as well. These data have been summarized in the comparison plots in Fig. 3.

Extended Data Fig. 8 STEM images for dislocation activities in the FCC/L12 matrix and B2 precipitates.

a1, The STEM image showing dislocation cutting across L12 in the FCC/L12 matrix (750 °C-1hr) at 5% strains, a2, The corresponding SAED. b1, The STEM image showing dislocation slip and accumulation in the deformable B2 precipitate (in HEA05 alloys, 750 °C-1hr) at 5% strains rather than fracture in traditional hard/brittle intermetallics. b2, The corresponding SAED.

Extended Data Fig. 9 Transmission Kikuchi diffraction (TKD) analysis of deformed microstructure.

The TKD IPF map in a1-b1, Phase map in a2-b2, Kernel average misorientation (KAM) in a3-b3, and KAM plot of FCC and B2 phases showing the appreciable misorientation in the B2 phase in c.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sohail, Y., Zhang, C., Xue, D. et al. Machine-learning design of ductile FeNiCoAlTa alloys with high strength. Nature (2025). https://doi.org/10.1038/s41586-025-09160-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41586-025-09160-2